Introduction to Polytetrafluoroethylene (PTFE) Tubing

Polytetrafluoroethylene (PTFE) Tubing, also known as PTFE Pipe in English, is a tubular product made from PTFE resin through specific processing techniques such as paste extrusion, compression molding, or extrusion. It is one of the most important and high-performance engineering plastic tubing products, renowned for its unparalleled chemical stability and broad temperature range.

The name directly highlights its core information:

- Material: Polytetrafluoroethylene (PTTE), commonly known as "Teflon" or the "King of Plastics."

- Form: Tubing/Pipe.

Key Characteristics

PTFE tubing inherits almost all the excellent properties of PTFE resin:

1. Exceptional Chemical Stability (Core Advantage): Resists almost all strong acids, strong alkalis, strong oxidizers, and organic solvents, including aqua regia. This is the primary reason it is called the "King of Plastics" and the key to its irreplaceability in the chemical industry.

2. Excellent High and Low-Temperature Performance: Can be used continuously within a temperature range of -180°C to +250°C without significant changes in mechanical properties. Short-term temperature resistance is even higher.

3. Extremely Low Coefficient of Friction: One of the lowest among solid materials, offering excellent lubrication, outstanding non-stick, and anti-adhesion properties.

4. Superior Electrical Insulation: Unaffected by environment and frequency, making it an ideal high-frequency, high-temperature insulating material.

5. Non-flammability: Limiting Oxygen Index (LOI) above 90, non-combustible, and self-extinguishing.

6. Physiological Inertness: Non-toxic, suitable for medical devices and the food industry (must comply with relevant standards).

Common Manufacturing Processes

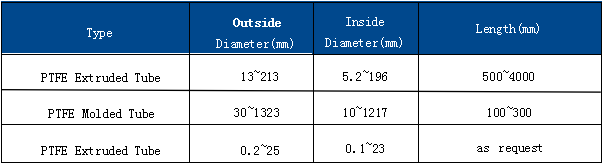

Depending on size and performance requirements, PTFE tubing is primarily produced through the following processes:

- Paste Extrusion:

- Process: PTFE dispersion resin is mixed with an extrusion aid (e.g., gasoline) to form a paste, which is then extruded under pressure through a paste extruder into a tubular shape. The tubing is then dried, sintered, and cooled.

- Characteristics: Most suitable for producing small-diameter, long-length thin-walled tubing. High production efficiency and the most commonly used process.

- Compression Molding and Sintering:

- Process: PTFE suspension resin powder is filled into a mold and compressed into shape, then sintered at high temperatures, and finally machined (turned) to the required dimensions.

- Characteristics: Suitable for producing large-diameter, thick-walled tubing. The material is dense with excellent performance, but size is limited, and costs are higher.

- Ram Extrusion:

- Process: Pre-pressed billets are placed into an extruder and continuously extruded under high temperature and pressure.

- Characteristics: Used for producing medium to large-diameter rods and thick-walled tubing.

Main Application Areas

The unique properties of PTFE tubing make it the preferred choice in harsh environments:

- Chemical Industry:

- Corrosive Media Transfer Pipes: Pipes, liners, and siphon tubes for transporting various highly corrosive chemicals such as acids, alkalis, chlorine, and bromine.

- Heat Exchanger Tubes: Used in heat exchangers in corrosive environments.

- Electronics and Electrical Industry:

- High-Temperature, High-Frequency Insulating Sleeves: Used for insulating and protecting wires and cables, especially in high-temperature or high-frequency environments.

- Insulation Layers for Coaxial RF Cables.

- Mechanical Engineering:

- Hydraulic and Pneumatic Systems: Used as high-temperature-resistant, corrosion-resistant sealing tubes and guide tubes.

- Oil-Free Lubrication Tubes: Used in mechanical components requiring self-lubrication.

- Semiconductor Industry:

- Pipes for transporting ultra-pure chemicals, such as etchants and slurries (CMP), without leaching ions to contaminate the media.

- Medical and Food Industries:

- Medical device catheters and transport tubes in food processing equipment (must use food-grade resin).

Reinforced PTFE Tubing

To overcome the mechanical shortcomings of pure PTFE, filled PTFE tubing is often produced by adding fillers. Common fillers include:

- Glass Fiber (GF): Improves wear resistance, compressive strength, and creep resistance.

- Graphite: Enhances self-lubrication and thermal conductivity.

- Carbon Fiber (CF): Increases strength, stiffness, and wear resistance.

- Bronze: Significantly improves thermal conductivity and compressive strength.

Filled tubing retains good corrosion resistance while greatly enhancing mechanical properties, making it suitable for wear-resistant and pressure-bearing applications.

Comparison with Other Plastic Tubing

| Property |

PTFE Tubing |

PFA Tubing |

PVDF Tubing |

PP Tubing |

| Chemical Stability |

Excellent |

Excellent |

Good |

Fair |

| Continuous Use Temp |

-180°C ~ +250°C |

-190°C ~ +260°C |

-40°C ~ +140°C |

0°C ~ +90°C |

| Coefficient of Friction |

Very Low |

Very Low |

Medium |

Medium |

| Transparency |

Opaque |

Translucent |

Translucent to Transparent |

Translucent to Transparent |

| Processing Difficulty |

Difficult |

Moderately Difficult |

Easy |

Easy |

| Cost |

High |

Very High |

Medium |

Low |

| Primary Advantage |

Ultimate corrosion resistance, ultra-wide temp range |

Melt-processable, high purity |

UV resistance, good strength |

Low cost, easy processing |

Polytetrafluoroethylene (PTFE) Tubing is a high-performance specialty tubing with exceptional chemical inertness and an ultra-wide operating temperature range as its core value.

- Core Value: It is an irreplaceable solution in highly corrosive and extreme temperature alternating conditions where metal or other plastic tubing cannot perform.

- Key Selection Factor: The appropriate pure PTFE tubing or filled PTFE tubing and the suitable manufacturing process (paste-extruded or molded-and-turned tubing) must be selected based on specific media, temperature, pressure, size, and cost requirements.